Tel: +86 21 5109 7921,+86 21 5109 0930

MS Series Automatic Strong Magnetic Iron Remover_copy

● Brand Name: JCI

● Model Number: MS

● Operating Mode: Automatic● Certification: ISO9001: 2000

● Housing Material: SS304/316L

● Applicable Viscosity Range:< 20,000cp

● Peak of the magnetic: 8000/1000/12000 G

● Design Temperature: < 80°C or customized

● Design Pressure: 0.6-1.0Mpa or customized

● Packing Details: Non-fumigation wooden box

● Customer design: Acceptable

● Supply Ability: 2000 Sets per Year

● Warranty: 1 year

● Applicable liquids: Resin, edible oil, coal oil, polymer, water, citric acid, fermented liquid, protein, sorbitol, adhesive, inks, coatings, fruit juice, cooling liquid, diesel oil, etc.

● Brand Name: JCI

● Model Number: MS

● Operating Mode: Automatic● Certification: ISO9001: 2000

● Housing Material: SS304/316L

● Applicable Viscosity Range:< 20,000cp

● Peak of the magnetic: 8000/1000/12000 G

● Design Temperature: < 80°C or customized

● Design Pressure: 0.6-1.0Mpa or customized

● Packing Details: Non-fumigation wooden box

● Customer design: Acceptable

● Supply Ability: 2000 Sets per Year

● Warranty: 1 year

● Applicable liquids: Resin, edible oil, coal oil, polymer, water, citric acid, fermented liquid, protein, sorbitol, adhesive, inks, coatings, fruit juice, cooling liquid, diesel oil, etc.

Product Description

Specification

Working Principle

Advantages

Application

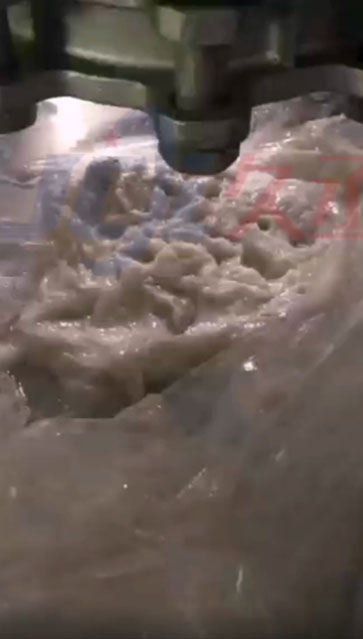

Automatic magnetic filter can be used to remove iron pollutants (e.g. rust and scrap iron) and other iron impurities. It can effectively improve the quality of products on production line and protect key equipment from the destruction by iron particles.

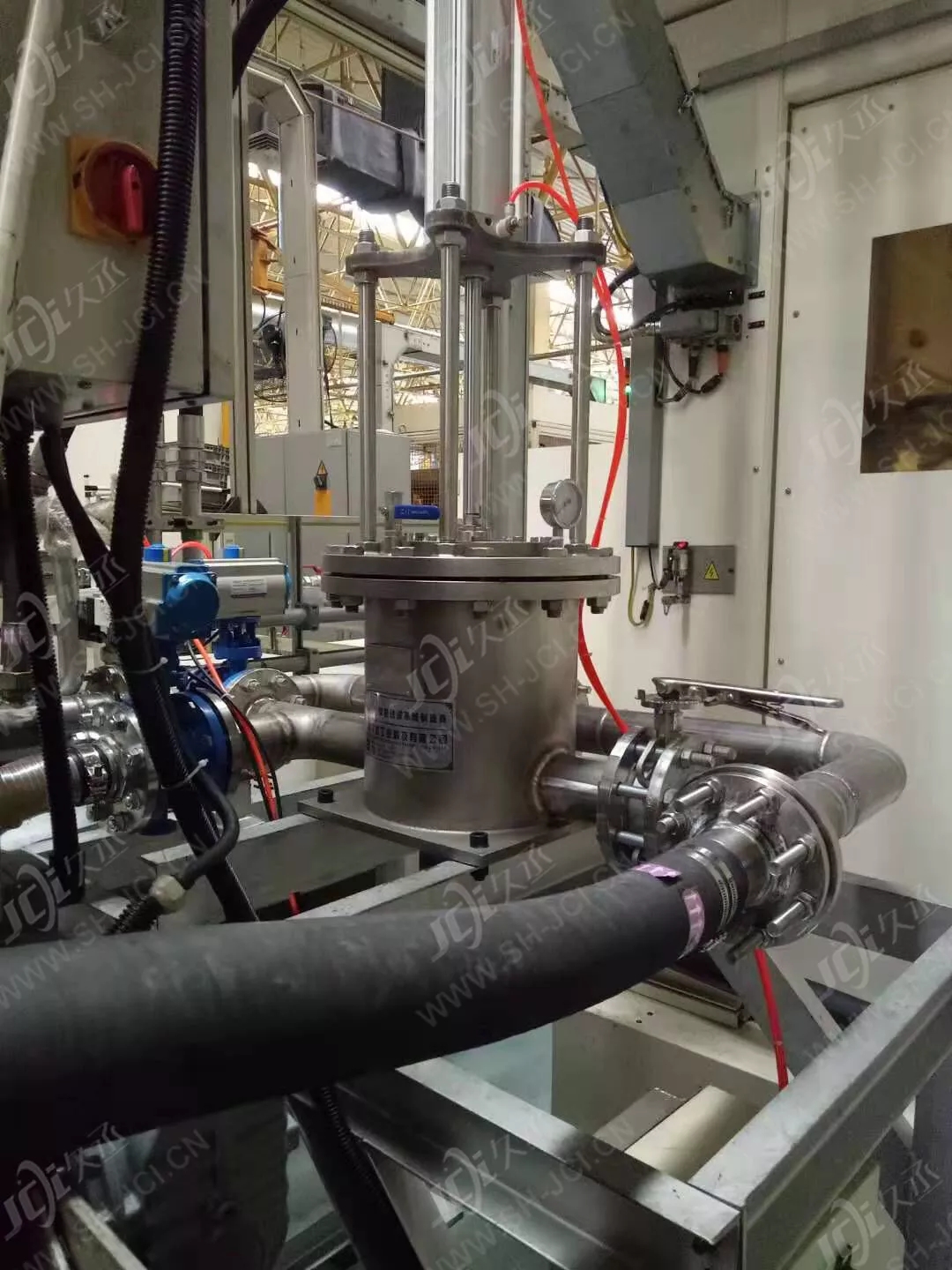

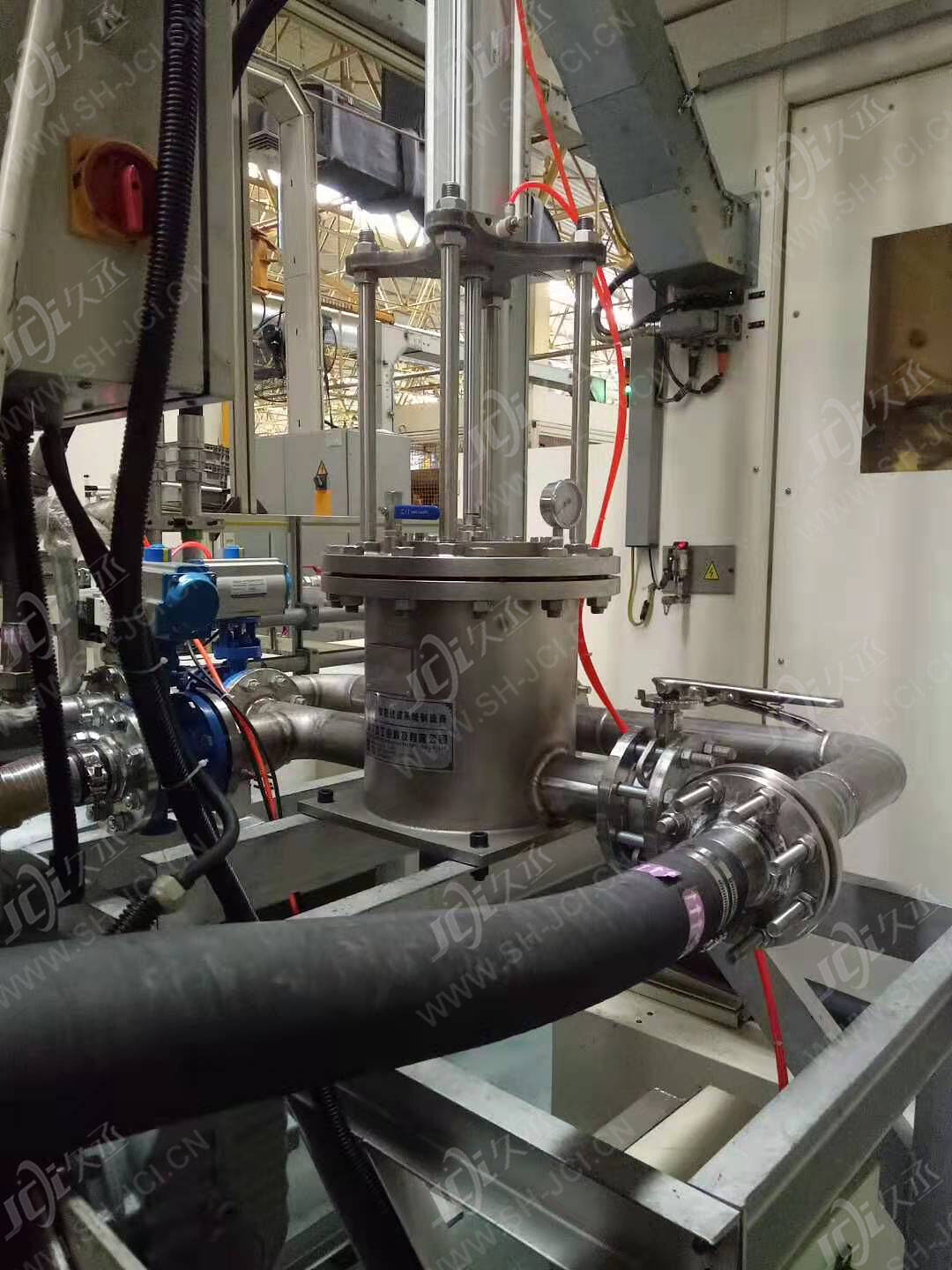

MS serise automatic magnetic filter is designed with optimal magnetic circuit and distribution of magnetic bar by using 3D finite element analysis method. The whole device is made of stainless steel. The magnetic bar is made of NdFeB superpower permanent magnetic material that is manufactured with updated technology. With the peak intensity of the surface magnetic field reaching 12000 Gauss, it is the top-class permanent magnetic material in the world. The roof cover is designed as quick-open type or sanitary clamp.

Product Details

Feedback

Related Product